Your silicone advisor

-

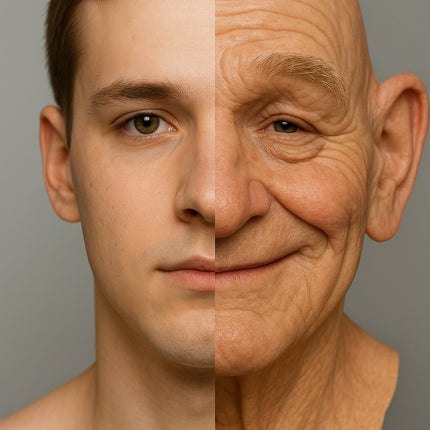

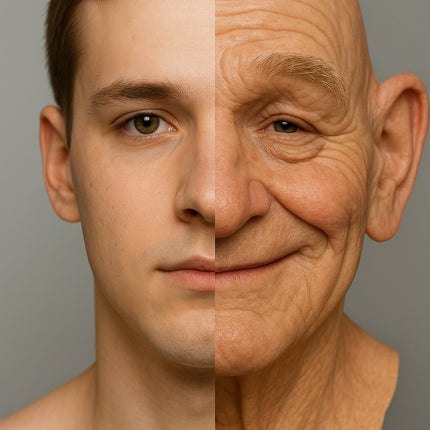

Silicone for Masks and SFX

Silicones for Special FX and Masks Want to create a realistic mask of an old man whose wrinkles move as

-

What Silicone works best with acrylic resin?

What is the best silicone to process acrylic resin from our own brand or Acrylic one or one of the

-

Silicone to make molds for pouring concrete or cement

Professional Silicone for Concrete Molds - High Quality Discover our extensive collection of silicone molds for concrete —specially developed for

-

Food safe silicone. Suitable for culinary food molds

Easily make molds with these two component silicones. All of the silicones mentioned are in fact food safe. Unfortunately, we

-

Silicone Molds for Epoxy Casting Resin - Resistant to Aggressive Resins

Silicone Molds for Epoxy Casting Resin - Professional Quality Discover our specialized collection of silicone molds for epoxy casting resin

-

-

-

Silicones for polyester casting resin

High-quality silicone for polyester casting resin Discover our extensive collection of professional silicones specially developed for use with polyester casting

-

-

Silicones for polyurethane casting resin

High-quality silicone for polyurethane casting resin Discover our extensive collection of professional silicones specifically designed for casting polyurethane resins. Whether

-

Professional silicone for production molds

Silicone Molds for Plaster and Plaster Impressions - Perfect Results Guaranteed Discover why silicone molds are the ideal choice for

-

-

Industrial tampon printing

An overview for Wacker print silicones: Elastosil RT Silicone Rubber For Pad Printing.pdf Here you will find silicones for industrial

-

Silicone Raw Materials Cosmetics - Emulsions, Silanes & Dimethicones

Silicones are synthetic compounds containing up to 60% silicon and oxygen—the most abundant elements in the Earth's crust. They are

What is the difference between addition and condensation silicone?

Simple explanation:

Condensation silicones, condensate. This means that condensation silicone sweats out some of its own material (tin salts). As a result, condensation silicone will shrink slightly in the long run. Assume 1% after one year. Condensation silicones are not food safe. These silicones are generally cheaper than addition silicones. Condensation silicones are easier to process.

Addition silicones show almost no shrinkage, but can react with certain materials / substances in the liquid state, causing poisoning of the silicones. These include sulfur, nitrogen, amino compounds and metal salts. Do a small test first if you are not sure whether your material reacts to the silicone. These silicones generally last longer and are also slightly more expensive.

For a detailed explanation: click here

Condensation Silicones:

Silicone Condensation 20: a good standard silicone for soap molds, candle molds, concrete molds, etc. Processing time 100-120 minutes. Curing time 16-20 hours.

Silicone Condensation DC 3481 F: professional silicone. Quick to deploy and very dry. Suitable for concrete, washing and soap, among other things. Processing time 30 minutes. Curing time 6 hours.

Silicone Condensation DC 3481 R: professional silicone. Very dry and suitable for forming more aggressive resins such as epoxy and polyurethane. Processing time 90-120 minutes. Curing time 24 hours.

Silicone Condensation Kneadable: ideal for shaping charms and small or flat objects. Processing time 10-20 minutes. Curing time 5 hours.

Addition Silicones: from soft to hard

Silicone Addition Gel 840 Clear: silicone gel. A.o. for pouring in electronics, where the measuring pins must still be accessible, but closed to moisture. Processing time 80 minutes. Curing time 24 hours.

Silicone Soft Flex 00-35: very stretchy and soft silicone. A.o. for masks, robotics, dolls, etc.

Processing time 6-8 minutes. Curing time 16-18 minutes.

Silicone Addition Clear 0 Supersoft: very soft and crystal clear. A.o. suitable for casting electronics and optical elements. Basically a firm gel. Processing time 50 minutes. Curing time 3 hours.

Silicone Wound: professional silicone to sculpt wounds and effects on the skin. Very soft, easy to apply, easy to shape. Processing time 2-4 minutes. Curing time 8-10 minutes.

Silicone Addition Clear 5: very soft and crystal clear. A.o. suitable for casting electronics and optical elements. Processing time 30 minutes. Curing time 2 hours.

Silicone Addition Colorless 5: very soft, stretchy silicone. Ideal for masks, delicate shapes, props and detailed candle molds. Processing time 30 minutes. Curing time 2 hours.

Silicone Addition Pink 10: soft, flexible silicone for fragile objects, candles, aggressive resins. Processing time 40 minutes. Curing time 4 hours.

Silicone Addition Transparent 15 Normal: soft, skin-friendly and food-safe. A.o. for prototyping, stamps (padding industry), prostheses and podology. Processing time 60 minutes. Curing time 6 hours.

Silicone Addition Transparent 15 Fast: soft, skin-friendly and food-safe. A.o. for prostheses, podology, prototyping. Processing time 2 minutes. Curing time 15 minutes.

Siliconen Culinair: ideal to make a mold for all your culinary creations. Food safe, Tüv certified. Specially developed for the catering industry. Processing time 60 minutes. Curing time 6 hours.

Silicone Addition Clear 25: medium hard, crystal clear silicone. A.o. suitable for casting in LEDs, optical elements, imitation of water and windows for modeling. Processing time 120 minutes. Curing time 20 hours.

Silicone Addition Yellow 25: medium hard silicone. Good resistance to aggressive casting resins such as epoxy, polyurethane and polyester. Processing time 60 minutes. Curing time 6 hours.

Silicone Elastosil M 4601 A/B: Good resistance to aggressive casting resins. Especially against polyurethane. Medium hard silicone for a firm dry mold. Can withstand higher temperatures for a short time. Processing time 90 minutes. Curing time 12 hours.

Silicone Addition Green 30: relatively hard silicone for sturdy molds. Good resistance to aggressive casting resins such as epoxy, polyurethane and polyester. Processing time 60 minutes. Curing time 6 hours.

Silicone Addition Transparent 40 Normal: hard and strong silicone. A.o. for prototyping, padding industry (stamps) prostheses and podology. Processing time 60 minutes. Curing time 6 hours.

Silicone Addition Transparent 40 Fast: hard and strong silicone. A.o. for prototyping, padding industry (stamps) prostheses and podology. Processing time 2 minutes. Curing time 15 minutes.

Silicone Addition Colorless 50: hard, sturdy but flexible silicone. A.o. suitable for concrete or other heavy casting masses. Processing time 30 minutes. Curing time 3 hours.

Plastique Culinair Fast: malleable, food-safe silicone. Very fast. Processing time 100 seconds. Hardening time 10 minutes.