Epoxy

-

Castable Epoxy

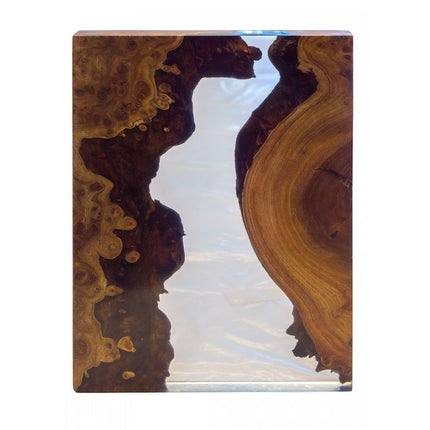

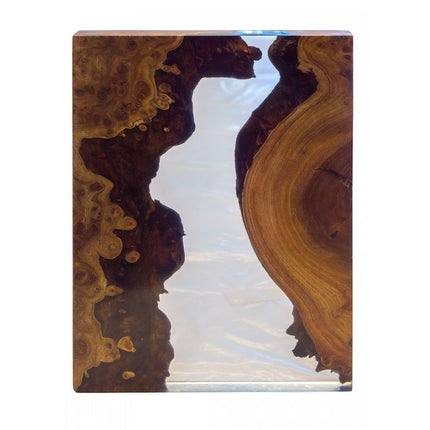

Epoxy casting resin for all applications With our epoxy casting resin, you can create crystal-clear castings for river tables ,

-

Epoxy for laminating

Epoxy lamination with fiberglass, carbon & Kevlar Laminating epoxy produces strong, durable laminates with excellent adhesion and low shrinkage. The

-

River Table Epoxy

Side table by Emiel Noorlander Epoxy for river table River tables are timelessly popular. With the right river table epoxy

-

Malleable Epoxy

Kneadable epoxy - professional modeling & repair epoxy Discover our selection of kneadable epoxy (epoxy putty) for sculpting, modeling, repairing,

-

-

Fillers, Metal Powders & Additives

Fillers, metal powders & additives Customize your resin or coating exactly how you want with our range of fillers ,

-

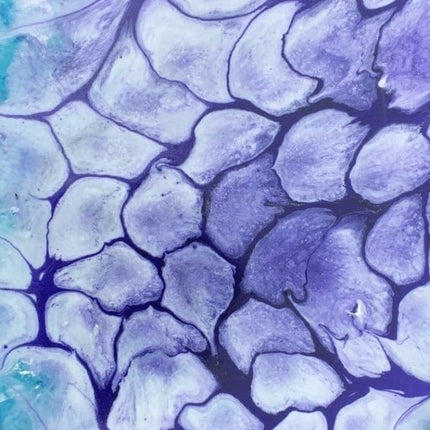

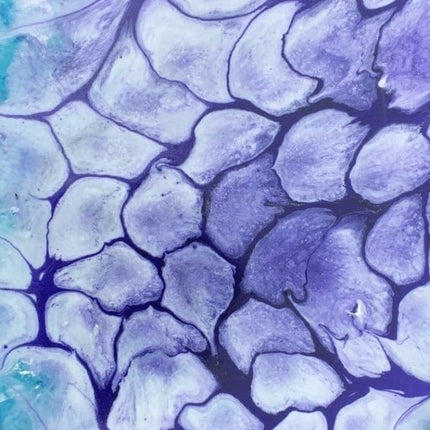

Dyes

Epoxy & Polyurethane Dyes Transform your epoxy and PU resin projects with our professional colorant collection. Specially selected for optimal

What is epoxy resin?

Epoxy is a versatile two-component resin for casting, laminating, coating, and bonding. When resin and hardener are mixed, a chemical reaction begins that creates long chains and a strong network. Depending on the formulation, you can achieve a flexible plastic or a glass-hard finish.

Epoxy works for clear art objects, river tables, and deep casting blocks, for electronics potting and protective coatings, for laminates with carbon, aramid, or fiberglass, and for repairs with epoxy glue or epoxy filler.

Compared to polyester, it has less odor, and compared to polyurethane, it is less sensitive to moisture. Always wear liquid-tight gloves, eye protection, and good ventilation.

What types of epoxy are there?

- • Two-component epoxy – the standard choice for casting, laminating, coating and bonding

- • One component UV curing epoxy – especially for 3D resin printers

- • Unfilled clear epoxy – for deep casting and art

- • Filled strong epoxy – for impact resistant parts

Epoxy applications

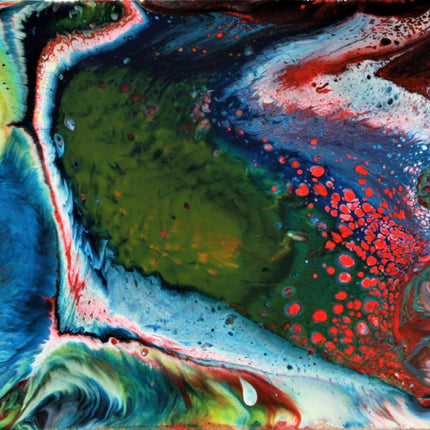

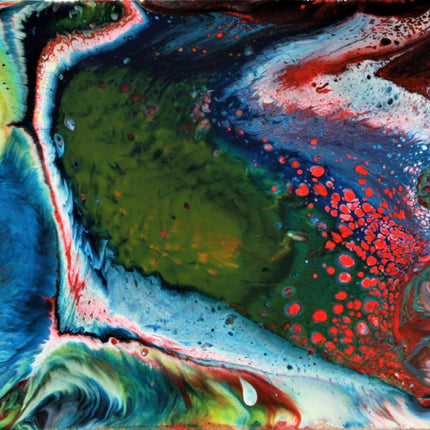

Casting Resin Epoxy

Many types of epoxy can be cast. Epoxy can be colored beautifully and filled with many different materials. The fillers make epoxy heavier or lighter, stronger and harder, or more flexible.

For example, filled epoxies are often used for climbing holds, DIY bowling balls, and many other impact-resistant products.

Clear Epoxy

Clear epoxy or clear resin is used for encapsulating or casting objects and cherished memories. With clear epoxy resin, you can cast large, clear blocks, create bright objects, and create beautiful river tables.

Embed electronics or create beautiful lighting effects. Crystal-clear epoxy resin is ideal for optical solutions.

Kneadable Epoxy

Kneadable epoxy is used for sculpting, filling, sealing, and repairing. There are various epoxy pastes for sculpting, such as the Aves Epoxie range.

In addition, there is a lightweight, kneadable epoxy that is quite strong after curing. Finally, there are filled, kneadable epoxy pastes that are very strong after curing.

Laminating Epoxy

Epoxy is a perfect resin for laminating. Combined with carbon fiber, aramid fiber, or fiberglass fiber, epoxy creates unparalleled laminate strength.

These laminates are also highly resistant to many chemicals and moisture. Ideal for laminating boats and reservoirs, sporting goods, and furniture.

Epoxy Glue

Epoxy adheres well to many surfaces, even without a primer. Almost all epoxy varieties can be used for gluing. However, the best adhesive epoxy is the universal epoxy because it cures relatively quickly.

FAQ Epoxy

Where can I dispose of my epoxy residue?

You can treat cured epoxy as regular waste. Any uncured material or packaging should be disposed of at a recycling center.

What is the best temperature to process epoxy?

Epoxy is best processed between 18 and 25°C. For larger quantities, we recommend lower temperatures. At higher temperatures, the processing time is very short.

Is Epoxy Dangerous or Harmful?

Liquid epoxy is definitely harmful. Always wear impermeable gloves, safety goggles, and work in a well-ventilated area. Don't work in your bedroom!

Is Epoxy Food Safe?

Many epoxy resins are generally food-safe for dry food at room temperature. However, you must have this tested by authorized agencies.

Why does my epoxy have an orange peel or wavy surface?

Surface imperfections in epoxy are caused by temperature fluctuations. Do not expose epoxy to sunlight, avoid drafts, and ensure the room remains approximately the same temperature throughout the entire curing process.

Why is my casting cloudy or hazy?

This could be due to two things: The mold and/or the original was matte, or there's amino blush. Amino blush is easily removed with soapy water and lukewarm water using a cloth.

Epoxy resins and their applications

Clear epoxy casting resins

Kneadable epoxies

Also check out our vlog

How to make your own bowling ball!

Click here for a table comparing various epoxy casting resins: