Buy Silicone Casting Rubber - Professional Silicone for Molds & Casting

-

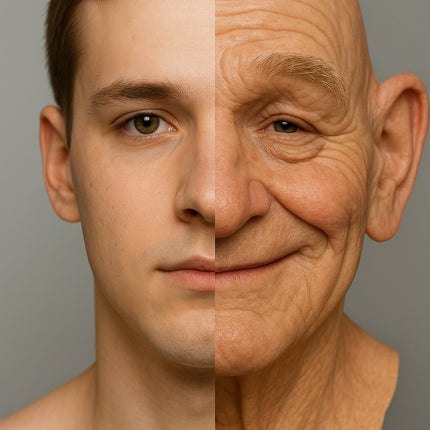

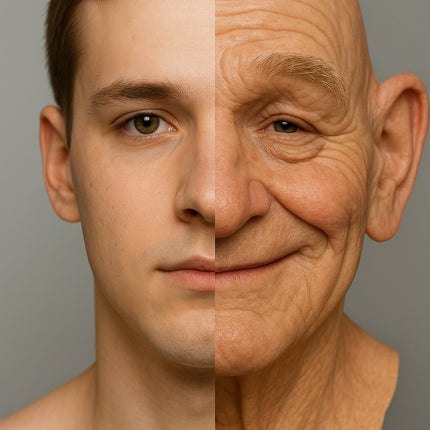

Silicone for Masks and SFX

Silicones for Special FX and Masks Want to create a realistic mask of an old man whose wrinkles move as

-

Best Silicones for Acrylic Resin | Acrylic One, Jesmonite & A1 Acrylic Resin

Best Silicone for Acrylic Resin Molds - Acrylic One, Jesmonite & A1 Discover the best silicone for acrylic resin molds

-

Silicone to make molds for pouring concrete or cement

Professional Silicone for Concrete Molds - High Quality Discover our extensive collection of silicone molds for concrete —specially developed for

-

Food-Safe Silicone - FDA Approved Silicone for Culinary Molds

Food-Safe Silicone for Culinary Molds Professional FDA approved silicone for making safe culinary molds Easily make molds with this two-component

-

Silicone Molds for Epoxy Casting Resin - Resistant to Aggressive Resins

Silicone Molds for Epoxy Casting Resin - Professional Quality Discover our specialized collection of silicone molds for epoxy casting resin

-

Silicone for Plaster & Porcelain Plaster - Making Plaster Molds

Professional Silicone for Plaster and Porcelain Plaster Molds Discover our extensive range of silicones for plaster molds , specially selected

-

Silicone for Candle Casting - Candle Molds & Wax Mold Making

Professional Silicone for Candle Casting and Wax Molds Discover our extensive range of silicones for candle casting , specially selected

-

Silicones for polyester casting resin

High-quality silicone for polyester casting resin Discover our extensive collection of professional silicones specially developed for use with polyester casting

-

-

Silicones for polyurethane casting resin

High-quality silicone for polyurethane casting resin Discover our extensive collection of professional silicones specifically designed for casting polyurethane resins. Whether

-

Professional silicone for production molds

Silicone Molds for Plaster and Plaster Impressions - Perfect Results Guaranteed Discover why silicone molds are the ideal choice for

-

Industrial tampon printing

Professional Silicone for Industrial Pad Printing Discover our collection of high-quality pad printing silicones from Wacker Chemie and CHT Group

-

Silicone Raw Materials Cosmetics - Emulsions, Silanes & Dimethicones

Silicones are synthetic compounds containing up to 60% silicon and oxygen—the most abundant elements in the Earth's crust. They are

-

Silicone Elastomers for Robotics & Animatronics

Professional Silicone Elastomers for Robotics and Animatronics Discover our extensive collection of high-quality silicone elastomers, specially selected for robotics and

-

Skin-friendly & Biocompatible Silicones

Professional Skin-Friendly and Biocompatible Silicones Discover our extensive range of skin-friendly silicones for medical applications, podiatry, prosthetics, special effects, and

-

Silicone for Textiles (printing, water-repellent, anti-slip etc)

Silicones and Textiles: Advanced Solutions for Printing, Comfort and Functionality Silicones play a key role in the modern textile industry.

-

Silicone Potting for Batteries - E-bikes, Cars, Drones & Quadcopters

Professional Silicone Potting for Lithium Batteries - E-bikes, Electric Cars, Drones & Quadcopters Lithium batteries in electric bicycles, electric cars,

-

Medical Simulation Silicone - Anatomical Models & Training Phantoms

Medical Simulation Silicone - Premium Materials for Realistic Training Models Medical simulation silicones are specially selected platinum-cured silicones that allow

-

Silicone for Making Soap and Candle Molds – Flexible, Precise, and Long-Lasting

Silicone Molds for Soap and Candles – Flexible, Detailed, and Durable Looking for the best silicone materials to create soap molds or candle

-

High Temperature Silicone

Heat-resistant RTV-2 silicone for extreme temperatures Silicone rubber is known as one of the most temperature-resistant elastomers. RTV-2 silicone, liquid

Silicone Casting Rubber - Your Complete Guide to Professional Silicone

Welcome to the ultimate silicone casting rubber collection from Siliconesandmore. Whether you want to make silicone molds , need industrial silicone , or are looking for food-grade silicone , we have the perfect solution for every application.

Platinum Silicone vs. Tin Silicone - The Difference Explained

Tin Silicone (Condensation Silicone) - Affordable & Easy to Use

Tin silicone , also called condensation silicone , is the most popular choice for beginners and hobbyists. This silicone casting rubber forms through condensation, which causes a small amount of material to bleed out.

Advantages of tin silicone:

- ✓ Cheaper than platinum silicone

- ✓ Easy to process

- ✓ Ideal for soap molds , candle molds and concrete molds

- ✓ Long processing time

Disadvantages of tin silicone:

- × Minimum shrinkage (±1% per year)

- × Not food safe

- × B component is less healthy

Platinum Silicone (Addition Silicone) - Premium Quality

Platinum silicone, or addition silicone, is the professional choice for high-quality applications. This silicone casting rubber exhibits virtually no shrinkage and offers superior performance.

Benefits of platinum silicone:

- ✓ No shrinkage

- ✓ Food-safe silicone available

- ✓ Longer lifespan

- ✓ Suitable for aggressive resins

- ✓ Skin-friendly

Disadvantages of platinum silicone:

- × More expensive than tin silicone

- × May react with certain materials (sulphur, nitrogen)

Silicone Categories - For Every Application

🏭 Industrial Silicone

Professional silicone casting rubber for industrial applications, prototyping, and production molds. Resistant to extreme temperatures and chemicals.

🍰 Culinary Silicone

Food-safe silicone for making chocolate molds, baking cups, and culinary creations. FDA-approved and TUV-certified.

🎭Special FX & Cosplay Silicone

Soft, skin-friendly silicone casting rubber for masks, prosthetics, and special effects. Perfect for film, theater, and cosplay.

🏗️ Building & Construction Silicone

Strong silicone molds for concrete, plaster, and other building materials. Ideal for precast elements and architectural details.

🕯️ Hobby & Creative Silicones

Easy-to-use silicone casting rubber for soap, candles, resin and other creative projects.

Complete Product Overview - All Silicones at a Glance

💎 Premium Platinum Silicone (Addition)

🔹 Very Soft Silicone (Shore A 0-10)

- Silicone Additive Gel 840 Clear - Transparent silicone gel specially developed for potting electronic components. Remains flexible after curing and protects against moisture while maintaining access to test pins. Processing time: 80 minutes, curing time: 24 hours.

- Silicone Soft Flex 00-35 - Extremely soft and stretchy silicone, ideal for realistic masks, robotics, and puppets. Shore A 00-35 hardness ensures natural movement and flexibility. Fast processing with a 6-8 minute pot life and 16-18 minutes of curing time.

- Silicone Additive Clear 0 Super Soft - Crystal-clear, ultra-soft silicone perfect for optical applications and electronic potting. Its combination of transparency and softness makes it ideal for delicate projects. Processing time: 50 minutes.

- Silicone Wound - Professional SFX silicone for creating realistic wounds and skin effects. Very soft, skin-friendly, and easy to apply. Popular in film, theater, and cosplay. Fast curing in 8-10 minutes.

- Silicone Addition Clear 5 - Very soft, crystal-clear silicone for optical elements and electronics. Shore A 5 hardness offers the perfect balance of softness and stability. Ideal for LED potting and light guiding. Processing time: 30 minutes.

- Silicone Additive Colorless 5 - Very soft, stretchable silicone, perfect for delicate molds and masks. Excellent detail reproduction and flexibility make it ideal for fine design. Suitable for fragile objects and detailed candle molds.

🔹 Soft Silicone (Shore A 10-25)

- Silicone Addition Pink 10 - Soft, flexible pink silicone, ideal for fragile objects and candles. Resistant to aggressive resins such as epoxy and polyurethane. Shore A 10 hardness offers perfect flexibility for delicate molds. Processing time: 40 minutes.

- Silicone Additive Transparent 15 Normal - Skin-friendly and food-safe silicone for medical applications, prototyping, and stamps. Transparent version with Shore A 15 hardness. Ideal for prosthetics, podiatry, and the pad printing industry. Processing time: 60 minutes.

- Silicone Additive Clear 15 Fast - A fast version of Clear 15 with identical properties but accelerated curing. Perfect for time-critical projects requiring skin compatibility and food safety. Processing time is only 2 minutes.

- Culinair® Silicone - Specially developed food-safe silicone for culinary molds. TÜV-certified and FDA-approved for direct food contact. Ideal for chocolate, fondant, ice cream, and other foods. Developed for the professional catering industry.

- Silicone Additive Clear 25 - Crystal-clear silicone with medium hardness for optical applications. Perfect for LED potting, water simulation, and model windows. Shore A 25 offers good stability while maintaining transparency. Processing time: 120 minutes.

- Silicone Additive Clear 25 Fast - A fast version of Clear 25 with identical optical properties. Ideal for projects requiring a fast turnaround without sacrificing clarity. Processing time: 30 minutes, curing time: 4 hours.

- Silicone Addition Yellow 25 - Yellow silicone with excellent chemical resistance to aggressive casting resins. Specially formulated for epoxy, polyurethane, and polyester applications. Shore A 25 hardness ensures durable molds. Processing time: 60 minutes.

- Colorless Silicone Additive 25 - Versatile silicone with medium hardness for general applications. A good balance of flexibility and strength makes it suitable for various projects. Its neutral color complements any application. Shore A 25 hardness.

🔹 Hard Silicone (Shore A 30-50)

- Silicone Addition Green 30 - Relatively hard green silicone for sturdy, durable molds. Excellent resistance to aggressive casting resins such as epoxy, polyurethane, and polyester. Shore A 30 hardness ensures dimensional stability with repeated use. Processing time: 60 minutes.

- Silicone Additive Clear 40 Normal - Hard, strong, transparent silicone for demanding applications. Ideal for prototyping, pad printing stamps, prosthetics, and podiatry. Shore A 40 hardness offers maximum durability. Skin-friendly and biocompatible.

- Silicone Additive Transparent 40 Fast - A fast version of Transparent 40 with identical mechanical properties. Perfect for production environments where fast turnaround is crucial. Maintains all the benefits of skin compatibility and strength. Processing time: 2 minutes.

- Silicone Additive Colorless 50 - Hard yet flexible silicone specially developed for heavy casting compounds such as concrete. Shore A 50 hardness offers the optimal balance between strength and flexibility. Ideal for architectural elements and construction applications.

- Elastosil M 4601 A/B Silicone - Professional industrial silicone with excellent resistance to aggressive casting resins, especially polyurethane. Medium-hardness silicone for strong, dry molds. Short-term temperature resistance. Processing time: 90 minutes.

🔹 Special Platinum Silicone

- Plastique Culinair® Fast - Kneadable food-safe silicone for quick culinary applications. Unique kneadable consistency allows for hand shaping. FDA-approved for direct food contact. Processing time: 100 seconds, curing time: 10 minutes.

- Elastosil RT 620 - Premium FDA-approved silicone for medical and pharmaceutical applications. Biocompatible and suitable for long-term skin contact. Used in medical devices and implants. Highest quality standards.

- SkinForm Silicone Addition - Specialized silicone for skin applications and prosthetics. Developed for a natural feel and appearance. Skin color and texture mimic real skin. Popular in medical and cosmetic applications.

🥈 Affordable Tin Silicone (Condensation)

🔹 Universal Tin Silicone

- Condensation Silicone 20 Universal - The most popular condensation silicone for general applications. Ideal for soap molds, candle molds, and concrete molds. Shore A 20 hardness offers the perfect balance between flexibility and strength. Processing time: 100-120 minutes.

- Silicone Condensation 20 Starter Kit - Complete set for beginners with everything you need to start making silicone molds. Includes basic silicone, hardener, instructions, and accessories. The perfect introduction to the world of silicone casting.

- Silicone Condensation 20 for PU and Epoxy - Specially formulated condensation silicone resistant to aggressive resins. Optimal performance when used with polyurethane and epoxy casting resins. Reduced reaction with aggressive chemicals. Shore A 20 hardness.

- Silicone Condensate 20 for Polyester - Optimized formulation for polyester casting resin applications. Minimal inhibition and excellent mold release in polyester projects. Proven performance in the fiberglass and polyester industries. Average Shore A 20 hardness.

🔹 Professional Tin Silicone

- Silicone Condensation DC 3481 Fast - Professional fast condensation silicone from Dow Corning. A very dry finish and fast application make it ideal for commercial production. Suitable for concrete, wax, and soap. Processing time: 30 minutes, curing time: 6 hours.

- Silicone Condensation DC 3481 R - Premium professional silicone with very dry properties. Specially developed for aggressive resins such as epoxy and polyurethane. Longer working time for complex projects. Processing time 90-120 minutes, curing time 24 hours.

- Condensation Silicone HT 60 - Heat-resistant, hard condensation silicone for extreme temperatures. Shore A 60 hardness combined with temperature resistance makes it ideal for industrial applications. Wacker Elastosil 4470 base with T40 hardener.

🔹 Soft Tin Silicone

- Silicone Condensation 5 Soft - Very soft condensation silicone for delicate applications. Shore A 5 hardness offers maximum flexibility for fine details and fragile objects. A-component combined with universal B-components.

- Silicone Condensation 35 - Moderately hard condensation silicone for stronger molds. Shore A 35 hardness ensures good dimensional stability while maintaining sufficient flexibility. A-component for use with universal hardener systems.

🔹 Kneadable Silicone

- Wacker Elastosil M 1470 Kneadable - Professional kneadable silicone from Wacker for manual shaping. Ideal for molding charms, small objects, and flat items. Processing time 10-20 minutes, curing time 5 hours. No mixing ratio required.

- Stensil ECO 20 Orange - Eco-friendly, kneadable silicone in orange. Shore A 20 hardness, perfect for hobby applications. Easy to knead and shape without tools. Suitable for beginners and educational purposes.

- Stensil ECO 30 Sand - Sand-colored, kneadable silicone with medium hardness. Shore A 30 offers a good balance between workability and end result. Its neutral color is suitable for various applications. Environmentally friendly ECO formulation.

- Stensil ECO 50 L Pink - Pink, kneadable silicone with medium hardness for decorative applications. Shore A 50 hardness ensures stable results. Popular for artistic projects and hobby applications. Longer working time due to L-formulation.

- Stensil ECO 60 Orange - Harder orange kneadable silicone for stronger molds. Shore A 60 hardness, ideal for repeat use and production applications. Retains kneadability despite higher final hardness. Sustainable ECO formulation.

- Stensil ECO 70 Blue - Blue hard, kneadable silicone for professional applications. Shore A 70 hardness offers maximum durability and dimensional stability. Suitable for industrial prototyping and production support. Environmentally friendly formulation.

- Stensil ECO 95 Blue - Ultra-hard blue, kneadable silicone for extreme applications. Shore A 95 hardness ensures maximum stiffness and durability. Ideal for precision applications and long-term use. Highest hardness in the ECO series.

🔧 Tools & Accessories

- B2 - B-Component Universal - Universal hardener (B-component) for condensation silicone systems. Compatible with all A-components in the 5, 20, and 35 series. Standard mixing ratio ensures optimal curing and properties.

- B5 - B-Component Universal - Alternative universal hardener with a modified formulation. Suitable for all A-component condensation silicones. Offers slightly different processing properties for specific applications. Economical choice.

- T47 B Component Fast - Fast hardener for shortened curing times of condensation silicones. Ideal for time-critical projects requiring rapid demolition. Maintains all the properties of standard systems but with an accelerated reaction.

- T21 B Component - Special hardener optimized for resistance to aggressive materials. Reduces inhibition on contact with problematic substrates. Ideal for challenging applications where standard systems fail.

- Elastosil E43 Silicone Adhesive - Food-safe silicone adhesive for bonding silicone parts. FDA-approved for direct food contact. Clear curing and flexible bond. Ideal for repairs and assembly of culinary molds.

- Elastosil E43N Silicone Adhesive - A neutral version of E43 silicone adhesive with improved adhesion. Food-safe and suitable for various substrates. Does not release acetic acid during curing. Professional quality for critical connections.

🎨 Special Applications

- LSR Topcoat HE - Matting topcoat for silicone surfaces with friction-reducing properties. Creates a natural skin texture on silicone prostheses and masks. Reduces shine and improves grip. Professional finish for SFX and medical applications.

- Elastosil FX Slow - Slow-curing FX silicone for complex special effects projects. Extended processing time allows for detailed modeling. Popular in film and theater for realistic effects. Professional quality.

- Elastosil FX Thixo - Thixotropic FX silicone that doesn't run on vertical surfaces. Ideal for building volume and texture without support structures. Maintains shape during application. Essential for professional makeup effects.

- Elastosil M 4630 - Premium industrial silicone for high-quality production applications. Developed for extreme conditions and long-term use. Excellent mechanical properties and chemical resistance. Professional industrial quality.

- Elastosil RT 623 - Specialty silicone for specific industrial applications. Unique properties make it suitable for niche markets. Developed according to strict quality standards. Limited availability for special projects.

Why Choose Siliconesandmore?

- ✓ Largest range of silicone casting rubber in the Netherlands

- ✓ Expert advice for every application

- ✓ Fast delivery within 24 hours

- ✓ Professional quality at competitive prices

- ✓ Technical support from specialists

- ✓ Secure payment and reliable service

Do you have questions about which silicone casting rubber is best for your project? Contact our experts for personalized advice!